We talk a lot about the “Electric Sombrero of Death”. Here is an overview of what it means, and how it affects your distillery.

The electric sombrero of death is all about electrical classification/ classified areas.

Whenever you have a potential flammable vapor source within a building/ distillery, for example a still, you must consider electrical classification / classified areas. This takes into consideration a potential leak from a still or other source, where flammable vapor could be released. If it were to come into contact with an electric component or electrical wiring, it has the potential to start a fire. Electrical classification is required regardless of building occupancy or construction type, it is purely based on if you have a potential flammable vapor source in your building.

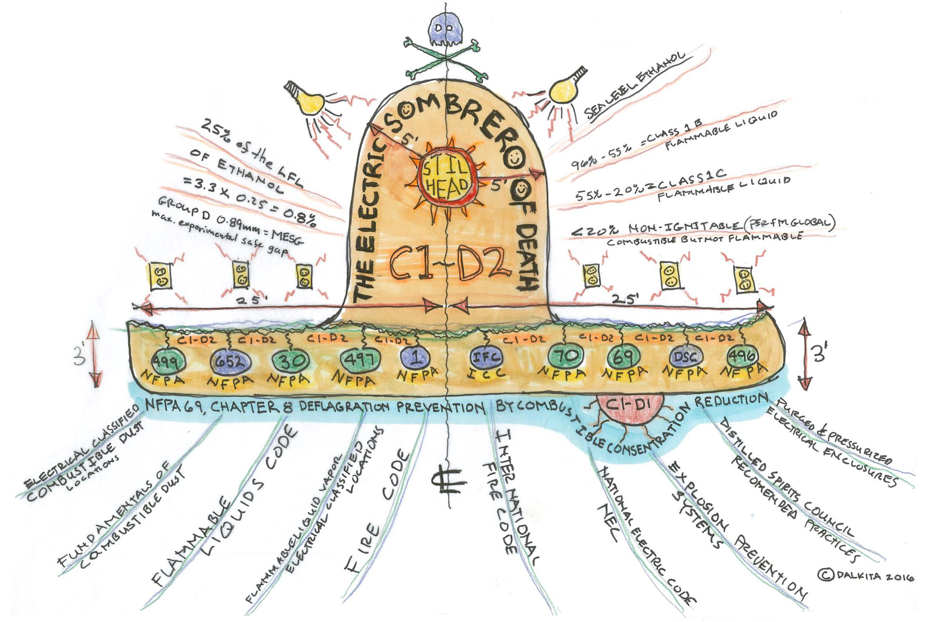

Below is a visualization of the many rules and physic surrounding this topic, created by Dalkita’s Scott Moore in 2016:

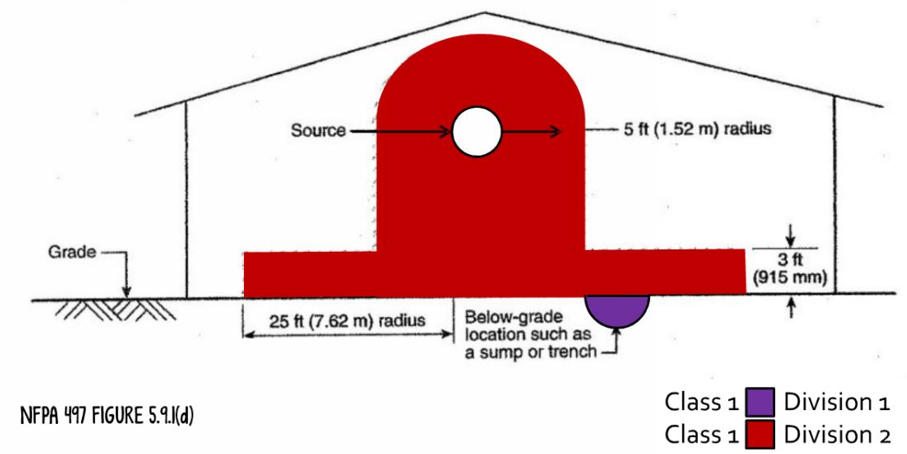

The “sombrero” shape is a derivative of diagrams found in NFPA 497, the Hazardous Location Classification standard. It essentially shows a potential vapor source (the white circle), which could be the head of your still. In 360 degrees surrounding the source, the classified area extend 5′. Then, within 3 ft of the floor, and 25′ horizontally in all directions, the classified area also exists. Basically, this says any electrics within this zone should be classified/ AKA explosion proof.

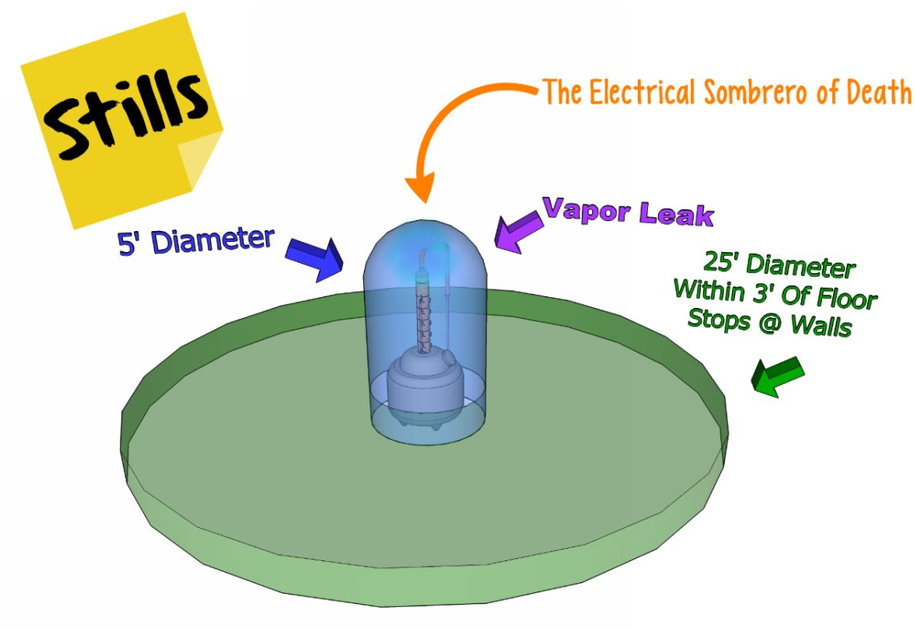

Here is another 3D visualization of this classified areas zone:

What are classified electrics?

Classified electrics are essentially equipment/ fittings that keep out potential flammable vapors. There are varying levels of classification. Sometimes, this is referred to as explosion proof, although that term is not always accurate when describing the actual classification required. Classified electrical equipment can often cost much more than non-classified equipment. Below is an example of a very pricey classified exit sign:

BUT!! We CAN eliminate the classified areas!

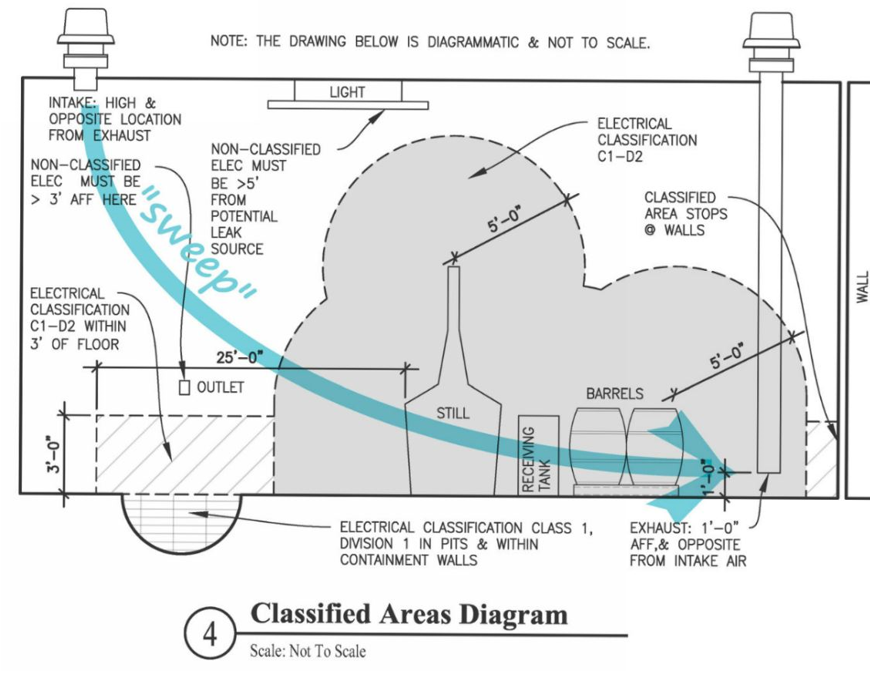

The IFC and NFPA has provisions for eliminating the classified areas. They allow this, if it can be demonstrated that <25% of the LFL (lower flammable limit) is maintained at all times. We can simply achieve this with exhaust. Dalkita often performs electrical declassification calculations to determine the exhaust rate needed to maintain <25% of the LFL. Therefore, we can declassify the space. The Electric sombrero is no longer really applicable, and we can have non-classified electrics within any area. Below is a digram showing how we often design ventilation systems in distilleries, essentially sweeping air across spaces and from low to high to ensure proper airflow.

Other considerations

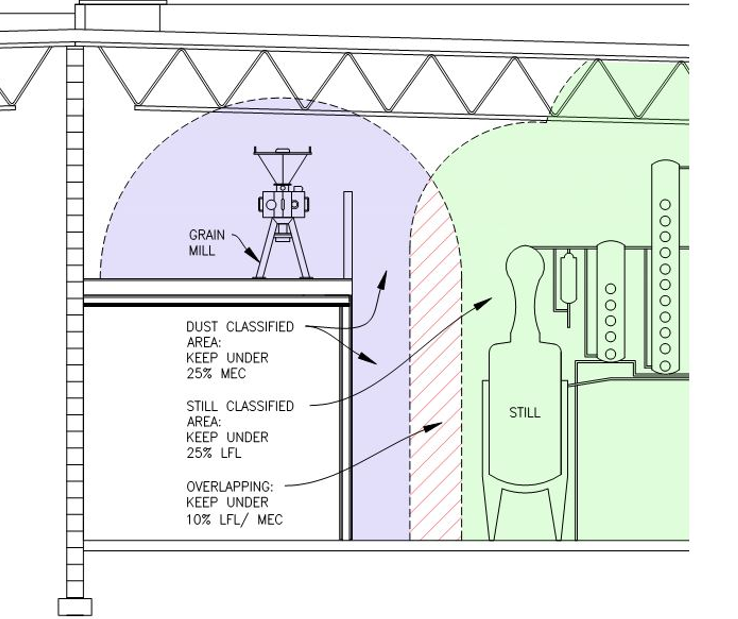

Codes also have requirements for classified areas around milling. If you have milling near a still, it is generally not considered safe because the potential of flammable vapor and dust is very flammable.

In addition to stills and mills, barrels, and tanks should also be considered a potential vapor source. As well as theorizing a potential spills from any of these vessels.

We often say, when designing a distillery, you can use “math or money” when it comes to classified areas. Meaning, you can leave classified areas as is and buy expensive equipment and be limited as to what can be moved into the classified areas. Or, we can do some math/ run calculations and install exhaust to prove the classified areas to be eliminated, giving you freedom to put whatever equipment wherever you need it.

If you want to learn more, a full presentation on this topic can be purchased from our website, click the button below:

Article by: Matthew Taylor-Rennert

Dalkita Inc

303-765-1295